When your tool is ready, we install it in one of our all-electric injection molding machines and your chosen material is loaded into the hopper.

When your tool is ready, we install it in one of our all-electric injection molding machines and your chosen material is loaded into the hopper. The Process Engine takes over by quickly analyzing key components within the injection molding process to ensure the most consistent and stress free production of your custom parts.

Our 30 to 450 ton electric machines use 80% less energy than hydraulic machinesand allows for a more controllable plastic injection process. This enables us to manufacture your parts with more consistency and at the best possible price.

Insert molding is the process of injection molding molten thermoplastic around ceramic or metal pieces placed in the injection molding cavity.These inserts can be threads or other attachment points enabling two or more custom parts to be assembled together reducing the need for secondary manufacturing and/or installation processes.Insert molding plastic parts is an effective and cost-efficient solution for reducing a products overall cost.

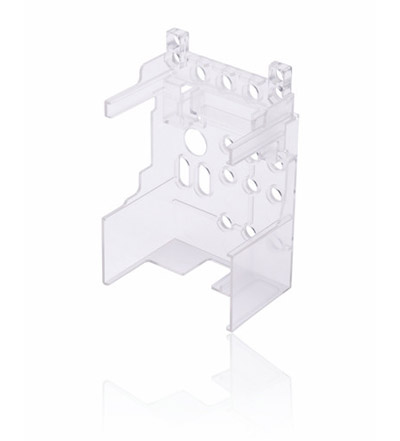

Part design, Mold Design and material selection are important when you are considering overmolding plastic parts.An overmolded plastic part can aid in wide range of functional and structural uses. Utilizing two separate injection molds, materials can be bonded together through the injection molding process to enhance the cosmetic looks and/or functionality of your finished plastic parts.

A popular design feature, injection molded threads give you the ability to fasten your plastic parts to other components securely with relative ease.Adding molded threads to your plastic part design can increase a parts functionality but if not carefully designed can add unforeseen costs into the manufacturing process.

Utilize low-shrinkage materials for parts with tight tolerances. Avoiding tight tolerance areas around the alignment of the mold halves or moving mold components such as sliders. Design your parts to avoid tight tolerance in areas prone to warpage or distortion. Our customers count on us for expert advice. With every injection molder you will hear the term "Tight Tolerance", unfortunately that term is thrown about loosely.

Also available are filled materials such as mineral filled, talc filled and glass filled which add extra strength and stability to a product. Custom color matching is available to ensure that your brand and products are being represented to spec. Costs saving suggestions are always made when they are consistent with our commitment to quality.

The process of making complex parts with injection molding depends on using scientific methods, the latest analytical tools and process technologies to ensure the resultant parts offer high quality performance. Usually, the process is divided into four stages. These stages are as follows:

Designing the complex part

Selecting the right material

Designing the mold

Process control

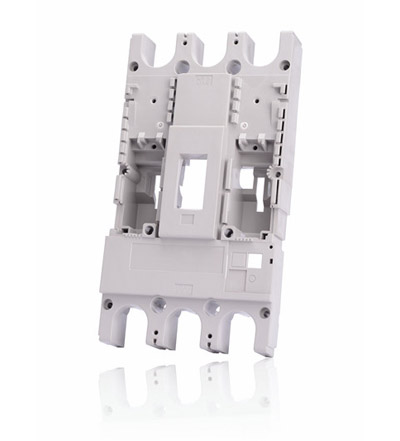

At CLS we have the capability of producing your custom parts with any number of undercuts. Our precision tooling and mold making technologies allows us to provide you the highest quality service that delivers the most complex plastic injection molded parts in the industry.

We personally stand behind every mold we build and run. Simply put you will never get a mold repair or rebuild invoice from us for the life of your project (unlimited Parts).

Multi-component injection molding combines different materials or dyes to produce high-quality plastic parts. This means you can improve the design and function of products, automatically and cost effectively. With us as your partner, everything is possible in terms of process engineering.

Our experienced sales engineers will quickly put together a comprehensive, interactive quote as well as a Manufacturability Analysis. Modify quantities, materials, surface finishes and more to find the perfect combination for your project and your budget...updated in real time. Anytime, anywhere.

Competitive pricing and our own advanced processes allows you, as a designer, to quickly compare pricing to find the optimal choice for your manufacturing requirements.

Here is specification list of all plastic injection molding machines for your reference :

| Brand | Model | Injection Speed | Plasticizing Capacity | Shot Weight (max) |

Distance Between Rods (HxV) |

Quantity |

| FUNAC | S2000-i30A | 525 mm/s | 13 kg/h | 22 (g) | 280x280 (mm) | 2 sets |

| FUNAC | S2000-i50B | 450 mm/s | 16 kg/h | 38 (g) | 320x320 (mm) | 2 sets |

| TOSHIBA | EC-100S | 500 mm/s | 61 kg/h | 94(g) | 460x410 (mm) | 1 sets |

| TOSHIBA | EC-130S | 350 mm/s | 83 kg/h | 145 (g) | 510x460 (mm) | 2 sets |

| TOSHIBA | EC-180S | 300 mm/s | 110 kg/h | 208 (g) | 560x510 (mm) | 1 sets |

| TOSHIBA | EC-230S | 300 mm/s | 160 kg/h | 361 (g) | 610x560 (mm) | 1 sets |

| TOSHIBA | EC-280S | 300 mm/s | 160 kg/h | 361 (g) | 730×660 (mm) | 1 sets |

| TOSHIBA | EC-350S | 300 mm/s | 230 kg/h | 780 (g) | 810×730 (mm) | 1 sets |

| VITOR Taichung | VS-100 | 186 mm/s | 41 kg/h | 110 (g) | 410x410 (mm) | 2 sets |

| VITOR Taichung | VS-180 | 152 mm/s | 110 kg/h | 315 (g) | 510x510 (mm) | 1 sets |

| VITOR Taichung | VS-250 | 145 mm/s | 166 kg/h | 541 (g) | 610x610 (mm) | 2 sets |

| HWA-CHIN | HC-80SE | 210 mm/s | 45 kg/h | 96 (g) | 330x330 (mm) | 1 sets |

| HWA-CHIN | HC-100SE | 190 mm/s | 50 kg/h | 127 (g) | 780x780 (mm) | 4 sets |

| HWA-CHIN | HC-450 | 81 mm/s | 190 kg/h | 1385 (g) | 380x300 (mm) | 1 sets |

| CLS | CLS-60 | 172 mm/s | 78 kg/h | 150 (g) | 380x300 (mm) | 1 sets |

| CLS | CLS-80 | 168 mm/s | 83 kg/h | 180 (g) | 410x350 (mm) | 1 sets |